20220721_103307

Welcome to Sensortronics

For all your weighing & product inspection needs

9E

DRBP_IMG_1686_Small

20200904_150206

tlb41

tlb41

20180605_112907

20230208_145043

TLB4_SEQUENZA VERTICALE 2

16

DRBP_IMG_1686_Small

Hybridpg copy

Hybridpg copy

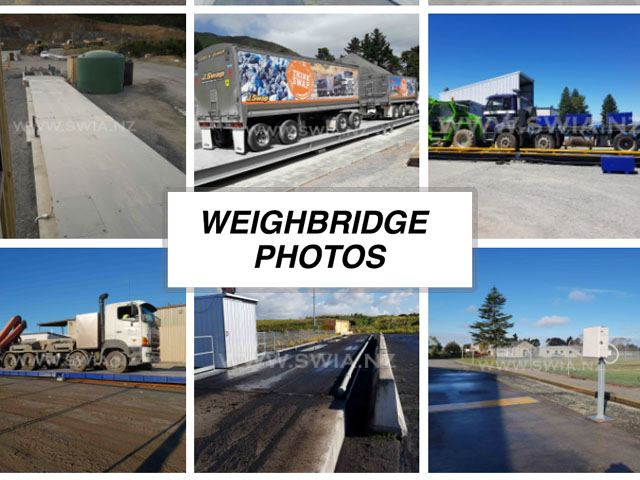

Weighbridge & Vehicle Weighing

Weighbridge & Vehicle Weighing

Bench & Counting Scales

Bench, Portable & Counting Scales

Platform & Floor Scales

Platform & Floor Scales

Medical & Veterinary Scales

Medical & Veterinary Scales

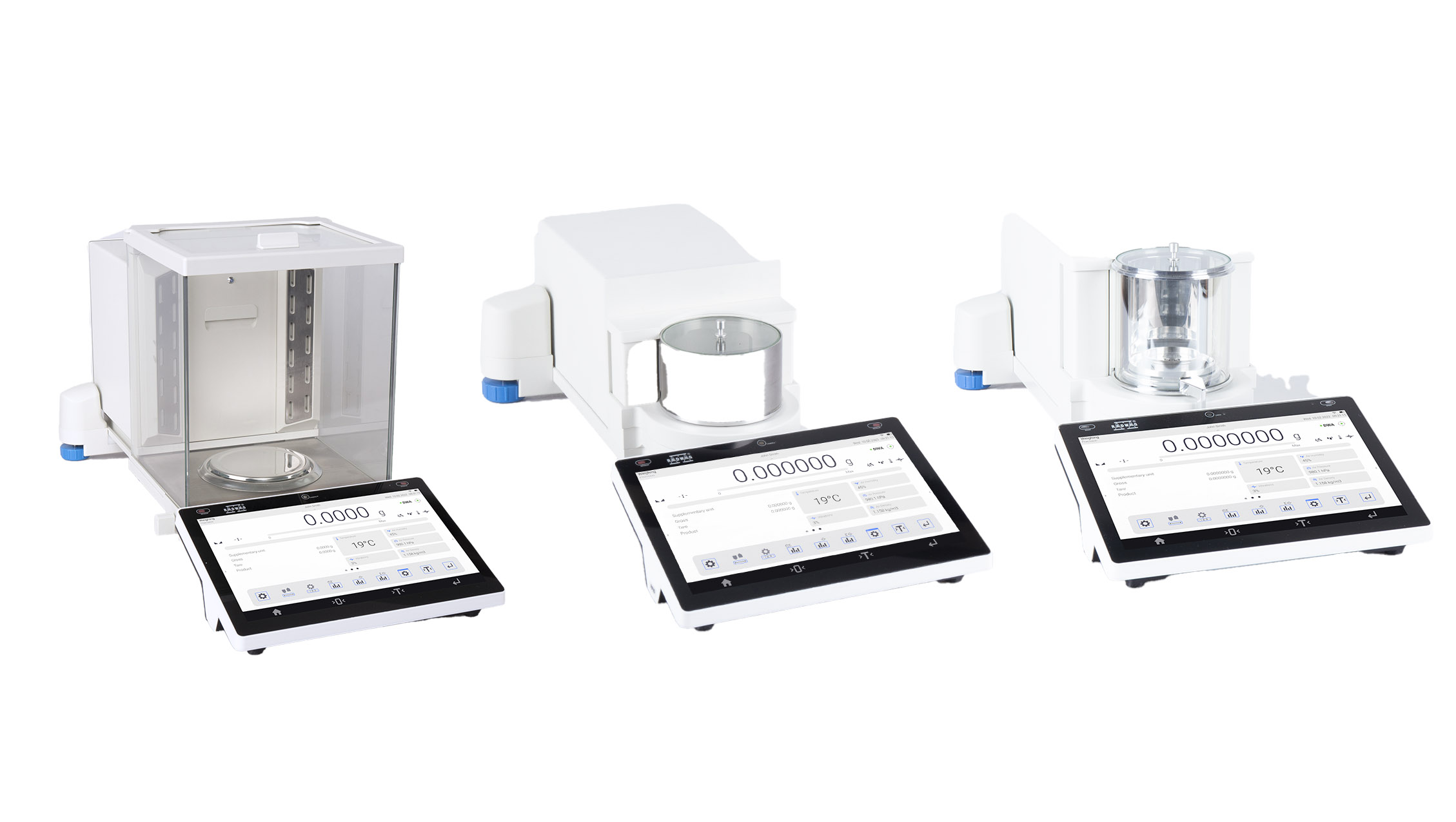

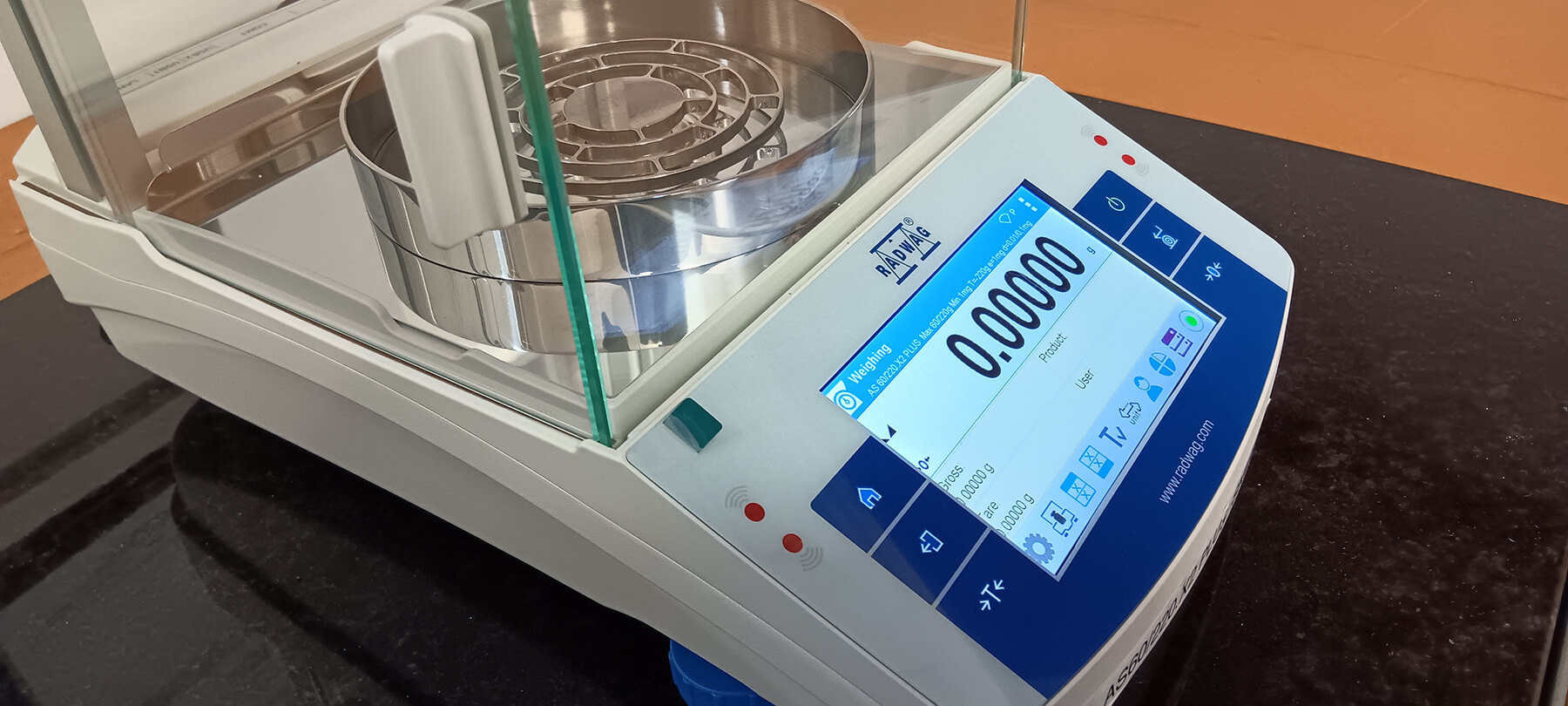

Laboratory Balances

Laboratory Balances

Accessories & Test Weights

Accessories & Test Weights

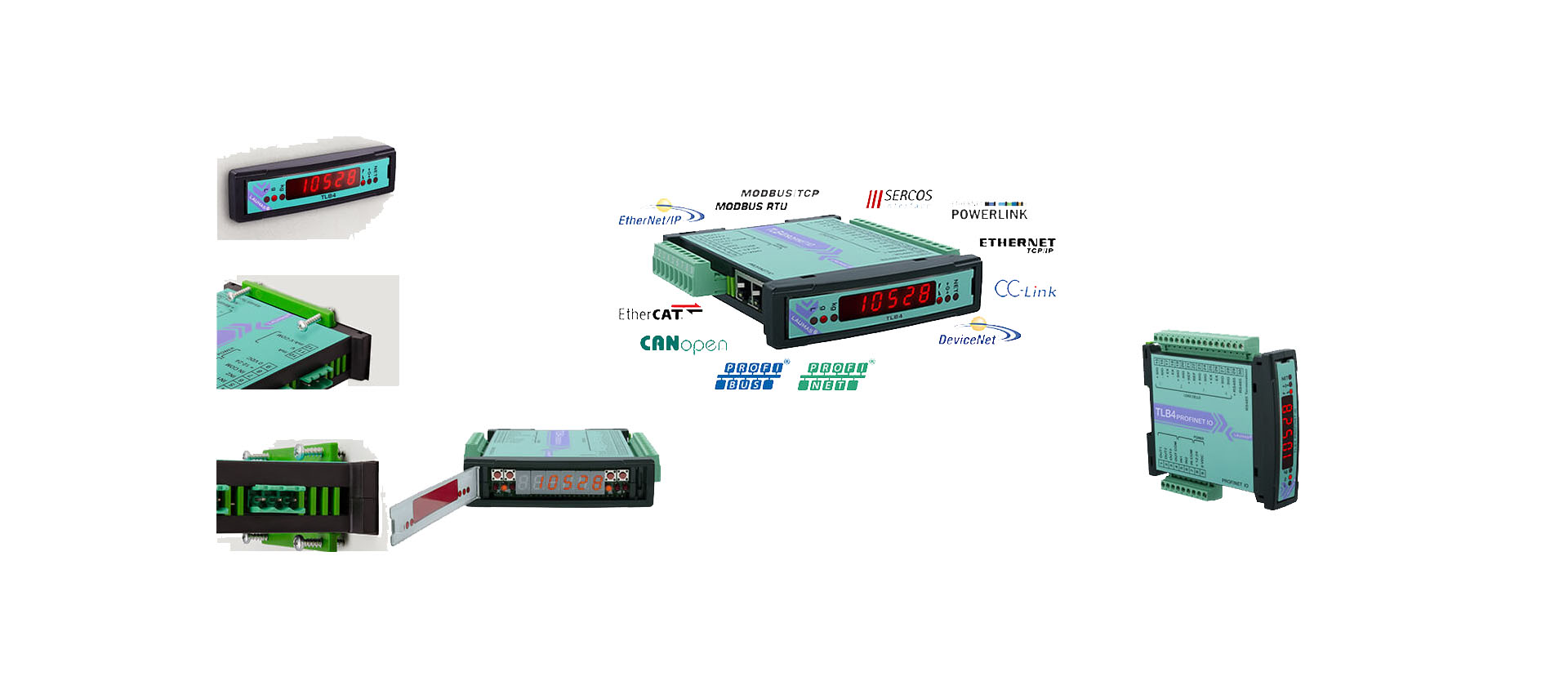

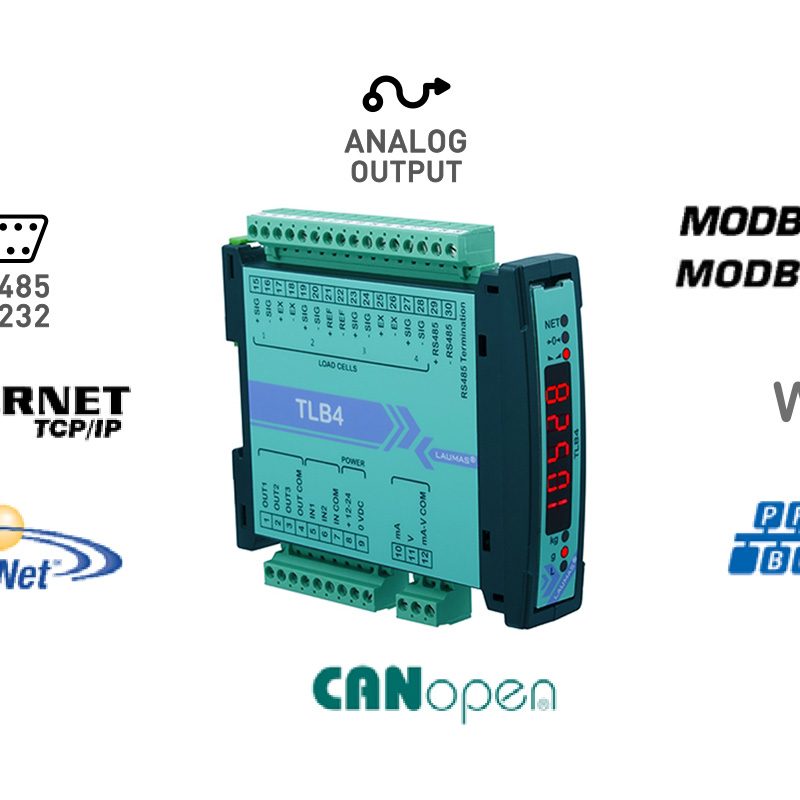

WEIGHING INDICATORS

WEIGHING INDICATORS

Weighing Software

Weighing Software

Load Cells & Mounts

Load Cells & Mounts

Retail & Price Computing Scales

Retail & Price Computing Scales

Hanging-Type & Crane Scales

Hanging-Type & Crane Scales

Hazardous Area Solutions

Hazardous Area Solutions

Product Inspection

Product Inspection

Industrial Automation

Industrial Automation

Dimensioning

Dimensioning

CALIBRATION-CERTIFICATION-SERVICE

CALIBRATION-CERTIFICATION-SERVICE

Hire / Rent Scales

Hire / Rent Scales

Sensortronic Group has been in the forefront of the weighing industry for over 30 years.

We supply scales for all situations from weighbridges, silos, belt weighers, “in motion” check weighing, to analytical balances, electronic platform scales and price computing scales. Sensortronic operates on a “quality first” philosophy, always remembering that ease of operation is of paramount importance.

Some of Our Projects

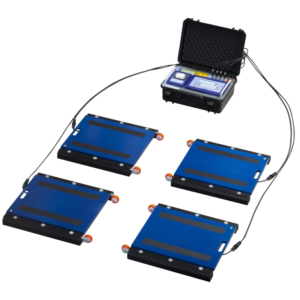

Introducing Dini Argeo Portable Vehicle Scales

WWS is the most cost-effective solution patented by Dini Argeo for weighing a vehicle.

Thanks to the low weight and ease of transport, in just a few minutes it is possible to create a weighing station for weighing 2-axle vehicles

Our Partners